ZVINHU ZVAKANYANYA

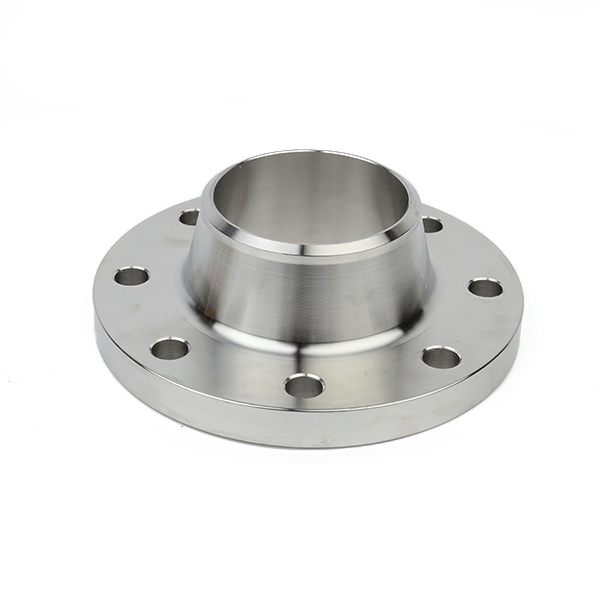

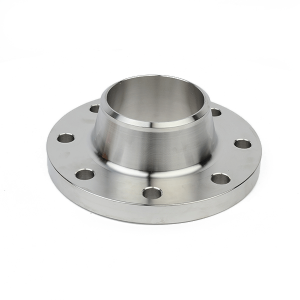

| Zita rechigadzirwa | Chibatanidzwa chemakumbo/Flange yakasununguka |

| Saizi | 1/2"-24" |

| Kumanikidzwa | 150#-2500#,PN0.6-PN400,5K-40K |

| Zvakajairika | ANSI B16.5, EN1092-1, JIS B2220 nezvimwe. |

| Mugumo we stub | MSS SP 43, ASME B16.9 |

| Zvinhu | Simbi isina ngura:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo nezvimwewo. |

| Simbi yekabhoni:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 nezvimwewo. | |

| Simbi isina ngura mbiri:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 nezvimwewo. | |

| Simbi yemapaipi:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 nezvimwewo. | |

| Nickel alloy:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 nezvimwewo. | |

| Cr-Mo alloy:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, nezvimwewo. | |

| Kushandiswa | Indasitiri yePetrochemical; indasitiri yendege nendege; indasitiri yemishonga; utsi hwegasi; chitubu chemagetsi; kuvaka ngarava; kurapwa kwemvura, nezvimwewo. |

| Zvakanakira | stock yakagadzirira, nguva yekutumira nekukurumidza; inowanikwa muhukuru hwese, yakagadzirirwa; yemhando yepamusoro |

ZVIYERO ZVE DIMENSION

RATIDZA RUDO RWEMAGADZIRWA

1. Chiso

Inogona kusimudzwa pachiso (RF), yakazara pachiso (FF), Ring joint (RTJ), Groove, Tongue, kana yakagadzirirwa iwe.

2. Mugumo weBevel zvichienderana neANSI B16.25

3.CNC fine yapera.

Kupedzisa kwechiso: Kupedzisa pachiso cheflange kunoyerwa seArithmetical Average Roughness Height (AARH). Kupedzisa kunotsanangurwa nechiyero chinoshandiswa. Semuenzaniso, ANSI B16.5 inotsanangura kupedzisa kwechiso mukati me125AARH-500AARH (3.2Ra kusvika 12.5Ra). Mamwe mafinishe anowanikwa kana uchida, semuenzaniso 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra kana 6.3/12.5Ra. Kupfuura 3.2/6.3Ra ndiko kwakajairika.

KUMAKA UYE KUPAKISA

• Rutivi rumwe nerumwe runoshandisa purasitiki kudzivirira pamusoro

• Kune simbi isingasvibi, mapuranga epurasitiki anoiswa mubhokisi replywood. Kuti mapuranga ecarbon flanges akwanise kukura, mapuranga anoiswa mubhokisi replywood. Kana kuti anogona kurongwa kuti agadziriswe.

• Chiratidzo chekutumira chinogona kuitwa kana chakumbirwa

• Zviratidzo pazvigadzirwa zvinogona kuvezwa kana kudhindwa. OEM inogamuchirwa.

KUONGORORA

• Kuongororwa kweUT

• Kuongororwa kwePT

• Kuongororwa kweMT

• Kuyedzwa kwehukuru

Tisati tasvika, timu yedu yeQC icharonga bvunzo yeNDT uye kuongororwa kwehukuru hwayo. Inogamuchirawo TPI (kuongororwa kwebato rechitatu).

MAITIRO EKUGADZIRA

| 1. Sarudza zvinhu zvepakutanga | 2. Cheka zvinhu zvakabikwa | 3. Kudziisa usati watanga |

| 4. Kugadzira | 5. Kurapa kupisa | 6. Kugadzira Machining Zvakaipa |

| 7. Kuboora | 8. Kugadzira zvakanaka | 9. Kumaka |

| 10. Kuongorora | 11. Kurongedza | 12. Kutumira |

Nyaya yekushandira pamwe

Iri purojekiti iri kuTurkey, maflange anoshandiswa mumapaipi egasi rechisikigo. Maflange ese iwayo anotenderwa neTUV.

PEJI REDHATA REFLANGE

1Zviyero zveFlange uye kushivirira zvinofanira kunge zvichienderana neASME B16.5.

2. Maflange anofanira kugadzirwa nekugadzira.

3. Zvinhu zvinofanira kunge zvichienderana neASTM A105, ASTM A694 F65 uye ASTM A694 F70.

4. Maflange eASTM A694 F65 neASTM A694 F70 anofanira kudzimwa uye kunyoroveswa.

5. Zvitupa zvekuyedza zvinhu uye mishumo yekurapa kupisa zvinofanira kuwanikwa kuti zviongororwe neTPI.

6. Maflange eWN anofanira kunge aine magumo e bevel acc. ku ASME B16.25.

7. Zvinhu zvekushandisa pakuongorora makemikari nemakemikari (kukanganisa, goho, kusimba nezvimwewo) zvinofanira kunge zvichienderana nezvinodiwa.

8. Nzvimbo dzese dzinofanira kunamirwa nemuchina uye kupendwa nemafuta anoonekera kuti dzisaita ngura.

9. Kumaka kunofanira kusanganisira ruzivo runotevera,

• Dhayamita (inopera 6”)

• Kirasi yekumanikidzwa (inopera 150 LB)

• Giredhi rezvinhu (yakapera ASTM A 105)

• Ukobvu hwemadziro (hunosvika 4,78 mm)

• Nhamba yekupisa (inopera 138413)

• Muyero wekugadzirwa (ASME B16.5)

10. Zvinhu zvinofanira kunge zvisina zvikanganiso pamusoro uye mitswe. Kugadzirisa welding hakubvumidzwe zvachose.

11. Maflange ese anofanira kunge akasimudzwa pachiso (RF) nepamusoro pekuvhara. Pamusoro pekuvhara panofanira kuva Ra 3,2 - 6,3 µm (125 - 250 mic. inc.) acc. kuASME B46.1.

12. Zvinhu zvinofanira kurongedzwa kudzivirira kukuvara kwemuchina wekugadzira, uye kuvhara pamusoro.

13. Zviyero zvese zvinofanira kunge zviri mu "positive" tolerances. "Minus tolerances" haibvumidzwe zvachose.

14. Mabhenekeri eFlange anofanira kuenderana neASME B16.25.

15. Maitiro ekugadzira achaongororwa chero nguva neTPI.

16. TPI inogona kutora sampuli kubva kune chero chinhu chemuenzaniso wekuyedza wemakemikari/makanika.

17. Mushumo wekuongorora unouya uchaongororwa neTPI.

| Chinhu | Saizi (Inch) | Kirasi Yekumanikidzwa | CS | Zvinhu | Huremu (mm) | Nzvimbo | Huwandu. |

| SORF | 12 | 150LB | 20 | A105 | - | Mafurangi eTangi | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | Mafurangi eTangi | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | Mafurangi eTangi | 32 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | Mafurangi eTangi | 2 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | Mafurangi eTangi | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | Mafurangi eTangi | 6 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | Mafurangi eTangi | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | Mafurangi eTangi | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 16 | Mafurangi eTangi | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | Mafurangi eTangi | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | Mafurangi eTangi | 6 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | Mafurangi eTangi | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | Mafurangi eTangi | 16 |

| Chinhu | Saizi (Inch) | Kirasi Yekumanikidzwa | CS | Zvinhu | Huremu (mm) | Nzvimbo | Huwandu. |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Weld Neck | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Weld Neck | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Weld Neck | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Weld Neck | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Weld Neck | 10 | 300LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Weld Neck | 6 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Weld Neck | 4 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Weld Neck | 18 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Weld Neck | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Weld Neck | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

Mibvunzo Inowanzo bvunzwa

1. Ndedzipi mhando dzakasiyana dzezvishandiso zvesimbi isina ngura zvinogadzirwa?

Mhinduro: Zvishandiso zvemapaipi esimbi isina ngura zvinosanganisira zvekushongedza mapaipi ehuku, zvekushongedza mapaipi esoketi, zvekushongedza mapaipi ane shinda, maflange, mavharuvhu nezvimwe.

2. Ndeupi musiyano uripo pakati pezvinhu zvinosungirirwa papombi dzesimbi isina ngura 304 ne316?

A: Simbi isingatsvi 304 yakakodzera kushandiswa kwakawanda uye ine simba rekudzivirira ngura. Simbi isingatsvi 316, kune rumwe rutivi, ine simba rekudzivirira ngura zviri nani munzvimbo dzine ngura zvakanyanya uye yakakodzera kushandiswa mugungwa nemakemikari.

3. Ndezvipi zvakanakira kushandisa forged butt welded pipe fittings?

A: Zvishandiso zve weld zvemagumbo zvakagadzirwa zvinopa simba rakawedzerwa, kuvimbika, uye kubatana kusina kudonha kwemvura. Zvinopa simba rakanaka rekudzivirira kukanganiswa uye zvinofarirwa kushandiswa pakumanikidzwa kwakanyanya uye kupisa kwakanyanya.

4. Chii chinonzi flange yekuwedera matako?

Mhinduro: Flange yekubatanidza mabutt iflange yepombi ine hub refu uye yakasungirirwa kupombi. Inopa shanduko yakatsetseka kubva papombi kuenda kune flange ine simba rakanaka uye yakavimbika.

5. Ndeipi mhando yesimbi isina ngura inowanzo shandiswa pakuisa pombi?

A: Simbi isina ngura 304, 316, 304L, 316L uye 317 dzinowanzoshandiswa muzvigadziko zvepombi nekuda kwekudzivirira kwayo ngura, kugara kwenguva refu uye kushandiswa kwakawanda.

6. Zvishandiso zvemapaipi esimbi isina ngura zvinogona kushandiswa here pakupisa kwakanyanya?

Mhinduro: Ehe, zvinhu zvesimbi isingatsvinda zvakakodzera kushandiswa pakupisa kwakanyanya. Zvisinei, mhando yesimbi isingatsvinda inoshandiswa inofanira kusarudzwa nokungwarira zvichienderana nezvinodiwa pakupisa kwekushandisa.

7. Zvishandiso zvemapaipi esimbi isingasvibi zvakakodzera here muindasitiri yezvikafu nezvinwiwa?

Mhinduro: Ehe, mapipe esimbi isina ngura anoshandiswa zvakanyanya muindasitiri yezvikafu nezvinwiwa nekuda kwehutsanana hwawo, kuramba ngura, uye nyore kugadzirisa.

8. Ndeupi musiyano uripo pakati pema socket welding fittings nema butt welding fittings?

Mhinduro: Zvishandiso zvemapaipi zvakasungirirwa pasoketi zvinoisa pombi musoketi zvobva zvaita welding yefillet kuti ibatanise pombi. Zvishandiso zveweld zvebutt, kune rumwe rutivi, zvinoda kuti magumo epombi apfumburwe uye ozobatanidzwa.

9. Zvishandiso zvepombi dzesimbi dzisina ngura zvinogona kudzokororwa here?

A: Ehe, zvinhu zvesimbi isina ngura zvinogona kushandiswazve. Simbi isina ngura chinhu chinogara kwenguva refu chinogona kushandiswazve uye kushandiswazve pasina kurasikirwa nehunhu hwayo kana kunaka kwayo.

10. Ndezvipi zvakanakira kushandisa zvinhu zvesimbi isina ngura zvichienzaniswa nezvimwe zvinhu?

A: Zvishandiso zvemapaipi esimbi isina ngura zvine mabhenefiti akawanda, akadai sekudzivirira ngura zvakanyanya, simba rayo guru, kugara kwenguva refu uye hutsanana. Hazvina kunyanya kugadziriswa, zvinogara kwenguva refu uye zvine chitarisiko chakachena uye chakanaka.

RATIDZA RUDO RWEMAGADZIRWA

1. Chiso

Inogona kusimudzwa pachiso (RF), yakazara pachiso (FF), Ring joint (RTJ), Groove, Tongue, kana yakagadzirirwa iwe.

2. Mugumo weBevel zvichienderana neANSI B16.25

3.CNC fine yapera.

Kupedzisa kwechiso: Kupedzisa pachiso cheflange kunoyerwa seArithmetical Average Roughness Height (AARH). Kupedzisa kunotsanangurwa nechiyero chinoshandiswa. Semuenzaniso, ANSI B16.5 inotsanangura kupedzisa kwechiso mukati me125AARH-500AARH (3.2Ra kusvika 12.5Ra). Mamwe mafinishe anowanikwa kana uchida, semuenzaniso 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra kana 6.3/12.5Ra. Kupfuura 3.2/6.3Ra ndiko kwakajairika.

KUMAKA UYE KUPAKISA

• Rutivi rumwe nerumwe runoshandisa purasitiki kudzivirira pamusoro

• Kune simbi isingasvibi, mapuranga epurasitiki anoiswa mubhokisi replywood. Kuti mapuranga ecarbon flanges akwanise kukura, mapuranga anoiswa mubhokisi replywood. Kana kuti anogona kurongwa kuti agadziriswe.

• Chiratidzo chekutumira chinogona kuitwa kana chakumbirwa

• Zviratidzo pazvigadzirwa zvinogona kuvezwa kana kudhindwa. OEM inogamuchirwa.

KUONGORORA

• Kuongororwa kweUT

• Kuongororwa kwePT

• Kuongororwa kweMT

• Kuyedzwa kwehukuru

Tisati tasvika, timu yedu yeQC icharonga bvunzo yeNDT uye kuongororwa kwehukuru hwayo. Inogamuchirawo TPI (kuongororwa kwebato rechitatu).

MAITIRO EKUGADZIRA

| 1. Sarudza zvinhu zvepakutanga | 2. Cheka zvinhu zvakabikwa | 3. Kudziisa usati watanga |

| 4. Kugadzira | 5. Kurapa kupisa | 6. Kugadzira Machining Zvakaipa |

| 7. Kuboora | 8. Kugadzira zvakanaka | 9. Kumaka |

| 10. Kuongorora | 11. Kurongedza | 12. Kutumira |

Nyaya yekushandira pamwe

Iri purojekiti iri kuTurkey, maflange anoshandiswa mumapaipi egasi rechisikigo. Maflange ese iwayo anotenderwa neTUV.

PEJI REDHATA REFLANGE

1. Zviyero zveFlange uye kushivirira zvinofanira kunge zvichienderana neASME B16.5.

2. Maflange anofanira kugadzirwa nekugadzira.

3. Zvinhu zvinofanira kunge zvichienderana neASTM A105, ASTM A694 F65 uye ASTM A694 F70.

4. Maflange eASTM A694 F65 neASTM A694 F70 anofanira kudzimwa uye kunyoroveswa.

5. Zvitupa zvekuyedza zvinhu uye mishumo yekurapa kupisa zvinofanira kuwanikwa kuti zviongororwe neTPI.

6. Maflange eWN anofanira kunge aine magumo e bevel acc. ku ASME B16.25.

7. Zvinhu zvekushandisa pakuongorora makemikari nemakemikari (kukanganisa, goho, kusimba nezvimwewo) zvinofanira kunge zvichienderana nezvinodiwa.

8. Nzvimbo dzese dzinofanira kunamirwa nemuchina uye kupendwa nemafuta anoonekera kuti dzisaita ngura.

9. Kumaka kunofanira kusanganisira ruzivo runotevera,

• Dhayamita (inopera 6”)

• Kirasi yekumanikidzwa (inopera 150 LB)

• Giredhi rezvinhu (yakapera ASTM A 105)

• Ukobvu hwemadziro (hunosvika 4,78 mm)

• Nhamba yekupisa (inopera 138413)

• Muyero wekugadzirwa (ASME B16.5)

10. Zvinhu zvinofanira kunge zvisina zvikanganiso pamusoro uye mitswe. Kugadzirisa welding hakubvumidzwe zvachose.

11. Maflange ese anofanira kunge akasimudzwa pachiso (RF) nepamusoro pekuvhara. Pamusoro pekuvhara panofanira kuva Ra 3,2 - 6,3 µm (125 - 250 mic. inc.) acc. kuASME B46.1.

12. Zvinhu zvinofanira kurongedzwa kudzivirira kukuvara kwemuchina wekugadzira, uye kuvhara pamusoro.

13. Zviyero zvese zvinofanira kunge zviri mu "positive" tolerances. "Minus tolerances" haibvumidzwe zvachose.

14. Mabhenekeri eFlange anofanira kuenderana neASME B16.25.

15. Maitiro ekugadzira achaongororwa chero nguva neTPI.

16. TPI inogona kutora sampuli kubva kune chero chinhu chemuenzaniso wekuyedza wemakemikari/makanika.

17. Mushumo wekuongorora unouya uchaongororwa neTPI.

| Chinhu | Saizi (Inch) | Kirasi Yekumanikidzwa | CS | Zvinhu | Huremu (mm) | Nzvimbo | Huwandu. |

| SORF | 12 | 150LB | 20 | A105 | - | Mafurangi eTangi | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | Mafurangi eTangi | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | Mafurangi eTangi | 32 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | Mafurangi eTangi | 2 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | Mafurangi eTangi | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | Mafurangi eTangi | 6 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | Mafurangi eTangi | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | Mafurangi eTangi | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 16 | Mafurangi eTangi | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | Mafurangi eTangi | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | Mafurangi eTangi | 6 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | Mafurangi eTangi | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | Mafurangi eTangi | 16 |

| Chinhu | Saizi (Inch) | Kirasi Yekumanikidzwa | CS | Zvinhu | Huremu (mm) | Nzvimbo | Huwandu. |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Weld Neck | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Weld Neck | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Weld Neck | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Weld Neck | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Weld Neck | 10 | 300LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Weld Neck | 6 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Weld Neck | 4 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Weld Neck | 18 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Weld Neck | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Weld Neck | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

Zvishandiso zvepombi zvinhu zvakakosha muhurongwa hwemapaipi, zvinoshandiswa pakubatanidza, kudzoreredza, kutsausa, kuchinja saizi, kuvhara kana kudzora kuyerera kwemvura. Zvinoshandiswa zvakanyanya mumabasa akadai sekuvaka, maindasitiri, simba uye mabasa emakanzuru.

Mabasa Akakosha:Inogona kuita mabasa akadai sekubatanidza mapaipi, kushandura nzira yekuyerera kwemvura, kupatsanura nekubatanidza kuyerera kwemvura, kugadzirisa dhayamita yemapaipi, kuvhara mapaipi, kudzora nekugadzirisa.

Mashandisirwo Ekushandisa:

- Kuvaka mvura uye nzira dzekubvisa mvura:Magokora ePVC nePPR tris zvinoshandiswa pakubatanidza mapaipi emvura.

- Mapaipi emaindasitiri:Maflange esimbi isina ngura uye magokora esimbi alloy anoshandiswa kutakura zvinhu zvine makemikari.

- Kutakurwa kwesimba:Zvishandiso zvesimbi zvine simba guru zvinoshandiswa mumapaipi emafuta negesi.

- HVAC (Kudziisa, Kufefetedza, uye Kutonhodza Mhepo):Zvishandiso zvemapaipi emhangura zvinoshandiswa kubatanidza mapaipi emufiriji, uye majoini anochinjika anoshandiswa kuderedza kudedera.

- Kudiridza kwekurima:Zvinobatanidza zvinokurumidza zvinoita kuti zvive nyore kuunganidza nekuputsa masisitimu ekudiridza sprinkler.

-

Pipe Fittings A105 Kirasi 150 Ss Carbon Steel Pl ...

-

Standard Pressure Orifice Flange Yakagadzirwa Stainle ...

-

mutsipa wesimbi yekabhoni weld mhando 6″ ANSI CLASS ...

-

simbi yekabhoni a105 forge blind BL flange

-

ASTM A182 F51 F53 BL ANSI B16.5 Simbi isina ngura...

-

Flange ye orifice WN 4″ 900# RF A105 dual gr ...