KUTAURA

| Product Name | socket weld flange |

| Size | 1/2"-24" |

| Pressure | 150#-2500#,PN0.6-PN400,5K-40K |

| Standard | ANSI B16.5, EN1092-1, JIS B2220 nezvimwe. |

| Kukora kwemadziro | SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS nezvimwe. |

| Material | Simbi isina ngura:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1, 50, 414. 54Mo uye nezvimwe. |

| Carbon steel:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 nezvimwewo. | |

| Duplex simbi isina tsvina:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 nezvimwe. | |

| Pipeline simbi:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 zvichingodaro. | |

| Nickel alloy:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 nezvimwe. | |

| Cr-Mo alloy:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, nezvimwewo. | |

| Application | Petrochemical industry; aviation and aerospace industry; pharmaceutical industry; gasi exhaust; power plant; ship building; water treatment, etc. |

| Zvakanakira | yakagadzirira stock, inokurumidza kuburitsa nguva; inowanikwa mune ese saizi, yakagadzirirwa; mhando yepamusoro |

DIMENSION MITIRO

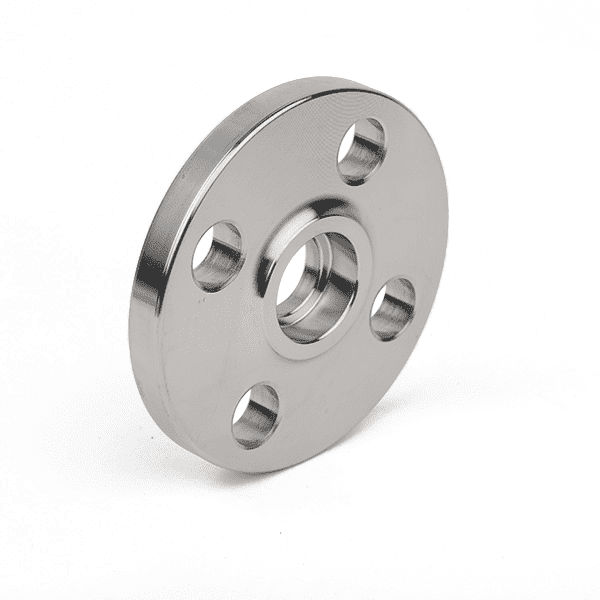

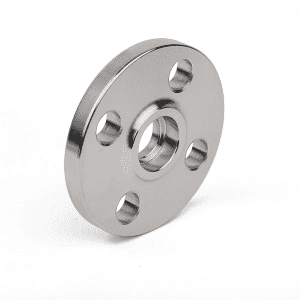

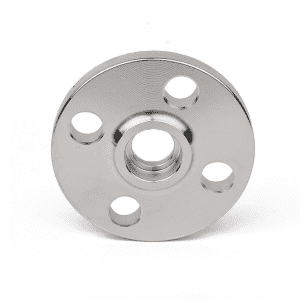

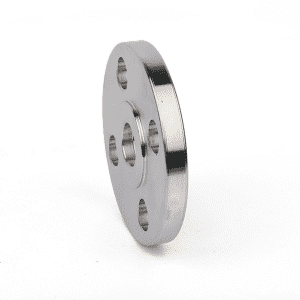

PRODUCTS DETAIL SHOW

1. Chiso

Inogona kusimudzwa chiso (RF), chiso chakazara (FF), Mhete yekubatanidza (RTJ) , Groove, Rurimi, kana yakasarudzika.

2.Socket weld

3.CNC yakanaka yapera

Kupera kwechiso: Kupedzisa kuri pachiso cheflange kunoyerwa seArithmetical Average Roughness Height(AARH).Kupedzisa kunotsanangurwa nechiyero chinoshandiswa.Semuenzaniso, ANSI B16.5 inotsanangura kupera kwechiso mukati mechikamu 125AARH-500AARH(3.2Ra kusvika 12.5Ra).Mamwe mapedziso anowanikwa pachikumbiro, semuenzaniso 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra kana 6.3/12.5Ra.Iyo yakawanda 3.2 / 6.3Ra ndiyo yakawanda.

KUMAKA NEKUPAKA

• Mutsara wega wega shandisa firimu repurasitiki kuchengetedza pamusoro

• Nokuti zvose Stainless simbi akazara plywood kesi.Kune yakakura saizi kabhoni flange yakarongedzwa neplywood pallet.Kana kuti inogona kugadziriswa packing.

• Mucherechedzo wekutumira unogona kuita pakukumbira

• Kutara pane zvigadzirwa zvinogona kuvezwa kana kudhindwa.OEM inogamuchirwa.

KUONGORORA

• UT bvunzo

• PT bvunzo

• MT bvunzo

• Dimension test

Tisati tasununguka, timu yedu yeQC icharonga NDT bvunzo uye chiyero chekuongorora. Uyewo gamuchira TPI (yechitatu bato kuongorora).

PRODUCTION PROCESS

| 1. Sarudza Genuine raw material | 2. Cheka mbishi | 3. Pre-kupisa |

| 4. Kugadzira | 5. Kurapa kwekupisa | 6. Rough Machining |

| 7. Kuchera | 8. Kuita zvakanaka | 9. Kumaka |

| 10. Kuongorora | 11. Kurongedza | 12. Delivery |

FAQ

1. Chii chinonzi ANSI B16.5 forged Stainless steel socket weld flange?

ANSI B16.5 Forged Stainless Steel Socket Weld Flange ndeye flange inoshandiswa kujoina mapaipi mukumanikidza kwakanyanya.Yakagadzirwa nesimbi yesimbi isina tsvina ine socket weld yekubatanidza kuitira nyore kuisa.

2. Ko ANSI B16.5 yakaumbwa nesimbi isina tsvina socket weld flanges yakasiyana sei nedzimwe mhando dzeflange?

Kusiyana nemamwe marudzi eflange, ANSI B16.5 yakaumbwa nesimbi isina simbi socket weld flange inoda socket weld yekubatanidza uko pombi inopinzwa muflange uye yakasungirirwa mukati.Izvi zvinopa mubatanidzwa wakasimba uye unodonhedza.

3. Ndezvipi zvakanakira kushandisa ANSI B16.5 forged Stainless steel socket weld flanges?

Mabhenefiti akakosha ekushandisa ANSI B16.5 forged Stainless simbi socket weld flanges anosanganisira kusimba kwepamusoro, kuvimbika uye yakanakisa corrosion resistance.Iwo akanakira maapplication anoda akasimba, akachengeteka majoini.

4. Ndeapi maindasitiri anowanzo kushandisa ANSI B16.5 forged Stainless steel socket welding flanges?

ANSI B16.5 forged Stainless steel socket weld flanges inowanzoshandiswa mumafuta uye gasi, petrochemical, makemikari, magetsi ekugadzira uye maindasitiri ekuchenesa mvura.Izvo zvakakodzerwa nepamusoro-soro uye kushandiswa kwekushisa kwepamusoro.

5. Ko ANSI B16.5 yakaumbwa nesimbi isina tsvina socket weld flanges inogona kushandiswa mugasi uye kushandiswa kwemvura?

Ehe, ANSI B16.5 forged Stainless simbi socket weld flanges inowanikwa kune gasi uye mvura yekushandisa.Izvo zvakagadzirirwa kupa kubatana kwakachengeteka uye zvinogona kumira kumanikidza uye tembiricha zvinodiwa zvehuwandu hwakawanda hwemvura.

6. Ndezvipi zviyero zvinotevedzwa pakugadzirwa kweANSI B16.5 forged Stainless steel socket weld flanges?

ANSI B16.5 Forged Stainless Steel Socket Weld Flanges inogadzirwa kune zviyero zvakatarwa neAmerican National Standards Institute (ANSI).Aya mazinga anovimbisa kuti flanges inosangana nemhando inodiwa uye kuita zvinodiwa.

7. Ko ANSI B16.5 forged Stainless steel socket weld flanges inowanikwa muhukuru hwakasiyana uye kudzvanywa ratings?

Ehe, ANSI B16.5 forged Stainless simbi socket weld flanges inowanikwa muhukuru hwakasiyana uye pressure ratings.Izvi zvinobvumira kuchinjika uye kuenderana neakasiyana pombi masisitimu uye zvinodiwa.

8. Ko ANSI B16.5 forged Stainless steel socket weld flanges inogona kushandiswa kusimudza uye flat surface connections?

Ehe, ANSI B16.5 forged Stainless simbi socket weld flanges inowanikwa kune ese akasimudzwa kumeso uye flat face yekubatanidza.Zviso zveFlange zvinogona kugadzirwa kuti zvisangane nezvinodiwa zvekushandisa.

9. Ko ANSI B16.5 forged Stainless steel socket weld flanges inokodzera kukwirisa tembiricha application?

Ehe, ANSI B16.5 forged Stainless simbi socket weld flanges inokodzera kupisa kwakanyanya.Izvo zvakagadzirirwa kutsungirira kupisa kwepamusoro pasina kukanganisa kuvimbika kwavo kwechimiro.

10. Ko ANSI B16.5 forged Stainless steel socket weld flanges inofanira kuiswa sei?

ANSI B16.5 Forged Stainless simbi socket weld flanges ichaiswa nenzira yekuti pombi inopinzwa musocket weld uye yakasungirirwa mukati.Zvakakosha kuve nechokwadi kuti welding yakakodzera inowanikwa kuchengetedza simba uye kuvimbika kwekubatana.

Zvigadzirwa zvakadzama zvinoratidza

1. Chiso

Inogona kusimudzwa chiso (RF), chiso chakazara (FF), Mhete yekubatanidza (RTJ) , Groove, Rurimi, kana yakasarudzika.

2.Socket weld

3.CNC yakanaka yapera

Kupera kwechiso: Kupedzisa kuri pachiso cheflange kunoyerwa seArithmetical Average Roughness Height(AARH).Kupedzisa kunotsanangurwa nechiyero chinoshandiswa.Semuenzaniso, ANSI B16.5 inotsanangura kupera kwechiso mukati mechikamu 125AARH-500AARH(3.2Ra kusvika 12.5Ra).Mamwe mapedziso anowanikwa pachikumbiro, semuenzaniso 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra kana 6.3/12.5Ra.Iyo yakawanda 3.2 / 6.3Ra ndiyo yakawanda.

Kumaka Uye Kurongedza

• Mutsara wega wega shandisa firimu repurasitiki kuchengetedza pamusoro

• Nokuti zvose Stainless simbi akazara plywood kesi.Kune yakakura saizi kabhoni flange yakarongedzwa neplywood pallet.Kana kuti inogona kugadziriswa packing.

• Mucherechedzo wekutumira unogona kuita pakukumbira

• Kutara pane zvigadzirwa zvinogona kuvezwa kana kudhindwa.OEM inogamuchirwa.

Inspection

• UT bvunzo

• PT bvunzo

• MT bvunzo

• Dimension test

Tisati tasununguka, timu yedu yeQC icharonga NDT bvunzo uye chiyero chekuongorora. Uyewo gamuchira TPI (yechitatu bato kuongorora).

Nzira yekugadzira

| 1. Sarudza Genuine raw material | 2. Cheka mbishi | 3. Pre-kupisa |

| 4. Kugadzira | 5. Kurapa kwekupisa | 6. Rough Machining |

| 7. Kuchera | 8. Kuita zvakanaka | 9. Kumaka |

| 10. Kuongorora | 11. Kurongedza | 12. Delivery |

-

Mugadziri ane hunyanzvi hwekuumba-high-pressure ...

-

forged asme b16.36 wn orifice flange naJack ...

-

AMSE B16.5 A105 forged kabhoni simbi weld mutsipa f...

-

ASTM A182 F51 F53 BL ANSI B16.5 Simbi isina tsvina...

-

ASME B16.48 CL150 CL300 Paddle spacer plank fla...

-

Socket weld flange A105 kabhoni simbi SW RTJ 3/4...