Tora basa rakazara rekugutsa zvese zvinodiwa kune vatengi vedu;kuwana kuenderera mberi nekusimudzira kufambira mberi kwevatengi vedu;kukura kuve wekupedzisira anogara akabatana mubatsiri wevatengi uye nekuwedzera zvinofarirwa nevatengi veFactory DN25 DN40 DN80 DN100 DN150 DN600 Weld Neck Forging Flanges, Kubatsira kweVatengi uye kugutsikana kazhinji ndicho chinangwa chedu chikuru.Rangarira kubata nesu.Tipe mukana, tikupe iwe zvinoshamisa.

Tora basa rakazara rekugutsa zvese zvinodiwa kune vatengi vedu;kuwana kuenderera mberi nekusimudzira kufambira mberi kwevatengi vedu;kukura kuve wekupedzisira anogara akabatana mubatsiri wevatengi uye nekuwedzera zvinofarirwa nevatengiChina Kugadzira Centrifugal Pump Flanges, Weld Neck Flanges, Kudzora kwakasimba kwehutano kunoitwa mune imwe neimwe yekubatanidza yezvese kugadzirwa process.Tine tarisiro yechokwadi yekumisikidza hushamwari uye kuwirirana-kunobatsira kubatana newe.Zvichienderana nemhinduro dzemhando yepamusoro uye yakakwana pre-sales / after-sales sevhisi ipfungwa yedu, vamwe vatengi vanga vashanda nesu kweanopfuura makore mashanu.

KUTAURA

| Product Name | Lap joint/Lose flange |

| Size | 1/2"-24" |

| Pressure | 150#-2500#,PN0.6-PN400,5K-40K |

| Standard | ANSI B16.5, EN1092-1, JIS B2220 nezvimwe. |

| Stub end | MSS SP 43, ASME B16.9 |

| Material | Simbi isina ngura:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1, 50, 414. 54Mo uye nezvimwe. |

| Carbon steel:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 nezvimwewo. | |

| Duplex simbi isina tsvina:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 nezvimwe. | |

| Pipeline simbi:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 zvichingodaro. | |

| Nickel alloy:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 nezvimwe. | |

| Cr-Mo alloy:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, nezvimwewo. | |

| Application | Petrochemical industry; aviation and aerospace industry; pharmaceutical industry; gasi exhaust; power plant; ship building; water treatment, etc. |

| Zvakanakira | yakagadzirira stock, inokurumidza kuburitsa nguva; inowanikwa mune ese saizi, yakagadzirirwa; mhando yepamusoro |

DIMENSION MITIRO

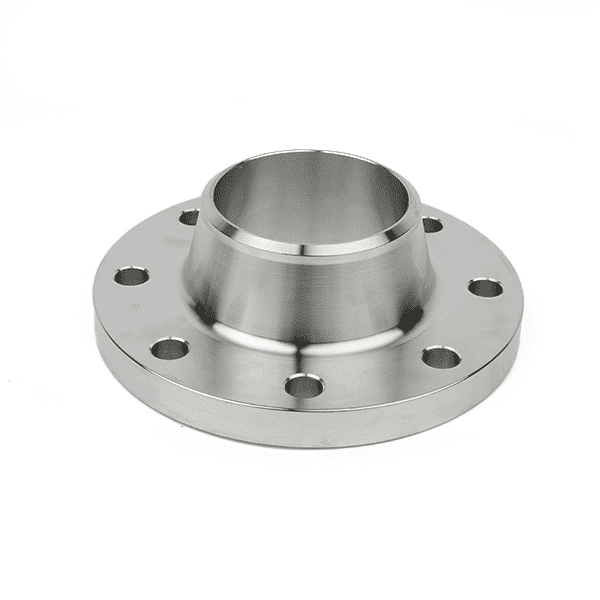

PRODUCTS DETAIL SHOW

1. Chiso

Inogona kusimudzwa chiso (RF), chiso chakazara (FF), Mhete yekubatanidza (RTJ) , Groove, Rurimi, kana yakasarudzika.

2.Bevel kupera se ANSI B16.25

3.CNC yakanaka yapera.

Kupera kwechiso: Kupedzisa kuri pachiso cheflange kunoyerwa seArithmetical Average Roughness Height(AARH).Kupedzisa kunotsanangurwa nechiyero chinoshandiswa.Semuenzaniso, ANSI B16.5 inotsanangura kupera kwechiso mukati mechikamu 125AARH-500AARH(3.2Ra kusvika 12.5Ra).Mamwe mapedziso anowanikwa pachikumbiro, semuenzaniso 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra kana 6.3/12.5Ra.Iyo yakawanda 3.2 / 6.3Ra ndiyo yakawanda.

KUMAKA NEKUPAKA

• Mutsara wega wega shandisa firimu repurasitiki kuchengetedza pamusoro

• Nokuti zvose Stainless simbi akazara plywood kesi.Kune yakakura saizi kabhoni flange yakarongedzwa neplywood pallet.Kana kuti inogona kugadziriswa packing.

• Mucherechedzo wekutumira unogona kuita pakukumbira

• Kutara pane zvigadzirwa zvinogona kuvezwa kana kudhindwa.OEM inogamuchirwa.

KUONGORORA

• UT bvunzo

• PT bvunzo

• MT bvunzo

• Dimension test

Tisati tasununguka, timu yedu yeQC icharonga NDT bvunzo uye chiyero chekuongorora. Uyewo gamuchira TPI (yechitatu bato kuongorora).

PRODUCTION PROCESS

| 1. Sarudza Genuine raw material | 2. Cheka mbishi | 3. Pre-kupisa |

| 4. Kugadzira | 5. Kurapa kwekupisa | 6. Rough Machining |

| 7. Kuchera | 8. Kuita zvakanaka | 9. Kumaka |

| 10. Kuongorora | 11. Kurongedza | 12. Delivery |

MHOSVA YEKUBATANA

A chirongwa muTurkey, flanges anoshandiswa mumapaipi egasi chaiwo.Ese maflange aya anotenderwa neTUV.

FLANGE DATA SHEET

1. Flange zviyero uye kushivirira kuchave maererano neASME B16.5.

2. Flanges ichagadzirwa nekugadzira.

3. Zvishandiso zvichave zvinoenderana neASTM A105, ASTM A694 F65 uye ASTM A694 F70 zviyero.

4. ASTM A694 F65 uye ASTM A694 F70 flanges ichadzimwa uye kutsamwa.

5. Material test zvitupa uye mishumo yekurapa kupisa ichaitwa kuti iwanikwe kuitira kuongororwa kweTPI.

6. WN flanges ichave ine bevel ends acc.kusvika kuASME B16.25.

7. Materials kemikari uye mechanical test values (impact, goho, tensile etc.) zvichava maererano nemitemo yakabatana.

8. Nzvimbo dzese dzichagadzirwa uye kuvharidzirwa nemafuta akajeka kudzivirira kuita ngura.

9. Kumaka kuchasanganisira ruzivo rwunotevera,

• Diameter (exp. 6”)

• Kirasi yepressure (exp. 150 LB)

• Chikamu Chekushandisa (exp. ASTM A 105)

• Ukobvu hwemadziro (exp. 4,78 mm)

• Heat No (exp. 138413)

• Mwero wekugadzira (ASME B16.5)

10. Zvishandiso hazvizove zvisina hurema hwepamusoro uye nekutsemuka.Welding kugadzirisa kunorambidzwa zvachose.

11. Maflange ese achasimudzwa kumeso (RF) aine chisimbiso chepamusoro.Nzvimbo yekuvharisa ichave Ra 3,2 – 6,3 µm (125 – 250 mic. inc.) acc.kuASME B46.1.

12. Zvishandiso zvichange zvarongedzerwa kudzivirira kukuvadzwa kumichina, uye kuvhara nzvimbo.

13. Zviyero zvese zvichave mune zvakanaka (+) kushivirira.Minus tolerances inorambidzwa zvachose.

14. Flange bevellings ichaitwa acc.kusvika kuASME B16.25.

15. Nzira yekugadzira ichaongororwa chero nguva neTPI.

16. TPI inogona kutora sampuli kubva kune chero chinhu chemakemikari/mechanical test sample.

17. Mushumo wekuongorora unouya uchaongororwa neTPI.

| Item | Saizi (Inch) | Pressure Kirasi | CS | Material | WT (mm) | Nzvimbo | Qty. |

| SORF | 12 | 150LB | 20 | A105 | - | TANK FLANGES | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | TANK FLANGES | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | TANK FLANGES | 32 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | TANK FLANGES | 2 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | TANK FLANGES | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | TANK FLANGES | 6 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | TANK FLANGES | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | TANK FLANGES | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 16 | TANK FLANGES | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | TANK FLANGES | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | TANK FLANGES | 6 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | TANK FLANGES | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | TANK FLANGES | 16 |

| Item | Saizi (Inch) | Pressure Kirasi | CS | Material | WT (mm) | Nzvimbo | Qty. |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Weld Neck | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Weld Neck | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Weld Neck | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Weld Neck | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Weld Neck | 10 | 300LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Weld Neck | 6 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Weld Neck | 4 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Weld Neck | 18 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Weld Neck | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Weld Neck | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

Tora basa rakazara rekugutsa zvese zvinodiwa kune vatengi vedu;kuwana kuenderera mberi nekusimudzira kufambira mberi kwevatengi vedu;kukura kuve wekupedzisira anogara akabatana mubatsiri wevatengi uye nekuwedzera zvinofarirwa nevatengi veFactory Outlets China Malleable DN25 DN40 DN80 DN100 DN100 DN600 Metal Decorative Pipe Fitting 304 Stainless Steel Weld Neck Forging Centrifugal Pump Flanges yedu yakakura mabhenefiti, chinangwa.Rangarira kubata nesu.Tipe mukana, tikupe iwe zvinoshamisa.

Factory Outlets China Forging Centrifugal Pump Flanges, Weld Neck Flanges, Strict quality control inoitwa mune imwe neimwe yekubatanidza yehurongwa hwese hwekugadzira.Tinotarisira nemoyo wese kumisa hushamwari uye hunobatsira-kubatirana pamwe newe.Zvichienderana nemhinduro dzemhando yepamusoro uye yakakwana pre-sales / after-sales sevhisi ipfungwa yedu, vamwe vatengi vanga vashanda nesu kweanopfuura makore mashanu.

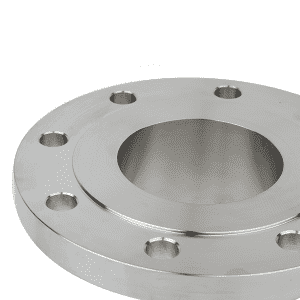

PRODUCTS DETAIL SHOW

1. Chiso

Inogona kusimudzwa chiso (RF), chiso chakazara (FF), Mhete yekubatanidza (RTJ) , Groove, Rurimi, kana yakasarudzika.

2.Bevel kupera se ANSI B16.25

3.CNC yakanaka yapera.

Kupera kwechiso: Kupedzisa kuri pachiso cheflange kunoyerwa seArithmetical Average Roughness Height(AARH).Kupedzisa kunotsanangurwa nechiyero chinoshandiswa.Semuenzaniso, ANSI B16.5 inotsanangura kupera kwechiso mukati mechikamu 125AARH-500AARH(3.2Ra kusvika 12.5Ra).Mamwe mapedziso anowanikwa pachikumbiro, semuenzaniso 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra kana 6.3/12.5Ra.Iyo yakawanda 3.2 / 6.3Ra ndiyo yakawanda.

KUMAKA NEKUPAKA

• Mutsara wega wega shandisa firimu repurasitiki kuchengetedza pamusoro

• Nokuti zvose Stainless simbi akazara plywood kesi.Kune yakakura saizi kabhoni flange yakarongedzwa neplywood pallet.Kana kuti inogona kugadziriswa packing.

• Mucherechedzo wekutumira unogona kuita pakukumbira

• Kutara pane zvigadzirwa zvinogona kuvezwa kana kudhindwa.OEM inogamuchirwa.

KUONGORORA

• UT bvunzo

• PT bvunzo

• MT bvunzo

• Dimension test

Tisati tasununguka, timu yedu yeQC icharonga NDT bvunzo uye chiyero chekuongorora. Uyewo gamuchira TPI (yechitatu bato kuongorora).

PRODUCTION PROCESS

| 1. Sarudza Genuine raw material | 2. Cheka mbishi | 3. Pre-kupisa |

| 4. Kugadzira | 5. Kurapa kwekupisa | 6. Rough Machining |

| 7. Kuchera | 8. Kuita zvakanaka | 9. Kumaka |

| 10. Kuongorora | 11. Kurongedza | 12. Delivery |

MHOSVA YEKUBATANA

A chirongwa muTurkey, flanges anoshandiswa mumapaipi egasi chaiwo.Ese maflange aya anotenderwa neTUV.

FLANGE DATA SHEET

1. Flange zviyero uye kushivirira kuchave maererano neASME B16.5.

2. Flanges ichagadzirwa nekugadzira.

3. Zvishandiso zvichave zvinoenderana neASTM A105, ASTM A694 F65 uye ASTM A694 F70 zviyero.

4. ASTM A694 F65 uye ASTM A694 F70 flanges ichadzimwa uye kutsamwa.

5. Material test zvitupa uye mishumo yekurapa kupisa ichaitwa kuti iwanikwe kuitira kuongororwa kweTPI.

6. WN flanges ichave ine bevel ends acc.kusvika kuASME B16.25.

7. Materials kemikari uye mechanical test values (impact, goho, tensile etc.) zvichava maererano nemitemo yakabatana.

8. Nzvimbo dzese dzichagadzirwa uye kuvharidzirwa nemafuta akajeka kudzivirira kuita ngura.

9. Kumaka kuchasanganisira ruzivo rwunotevera,

• Diameter (exp. 6”)

• Kirasi yepressure (exp. 150 LB)

• Chikamu Chekushandisa (exp. ASTM A 105)

• Ukobvu hwemadziro (exp. 4,78 mm)

• Heat No (exp. 138413)

• Mwero wekugadzira (ASME B16.5)

10. Zvishandiso hazvizove zvisina hurema hwepamusoro uye nekutsemuka.Welding kugadzirisa kunorambidzwa zvachose.

11. Maflange ese achasimudzwa kumeso (RF) aine chisimbiso chepamusoro.Nzvimbo yekuvharisa ichave Ra 3,2 – 6,3 µm (125 – 250 mic. inc.) acc.kuASME B46.1.

12. Zvishandiso zvichange zvarongedzerwa kudzivirira kukuvadzwa kumichina, uye kuvhara nzvimbo.

13. Zviyero zvese zvichave mune zvakanaka (+) kushivirira.Minus tolerances inorambidzwa zvachose.

14. Flange bevellings ichaitwa acc.kusvika kuASME B16.25.

15. Nzira yekugadzira ichaongororwa chero nguva neTPI.

16. TPI inogona kutora sampuli kubva kune chero chinhu chemakemikari/mechanical test sample.

17. Mushumo wekuongorora unouya uchaongororwa neTPI.

| Item | Saizi (Inch) | Pressure Kirasi | CS | Material | WT (mm) | Nzvimbo | Qty. |

| SORF | 12 | 150LB | 20 | A105 | - | TANK FLANGES | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | TANK FLANGES | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | TANK FLANGES | 32 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | TANK FLANGES | 2 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | TANK FLANGES | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | TANK FLANGES | 6 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | TANK FLANGES | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | TANK FLANGES | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 16 | TANK FLANGES | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | TANK FLANGES | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | TANK FLANGES | 6 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | TANK FLANGES | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | TANK FLANGES | 16 |

| Item | Saizi (Inch) | Pressure Kirasi | CS | Material | WT (mm) | Nzvimbo | Qty. |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Weld Neck | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Weld Neck | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Weld Neck | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Weld Neck | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Weld Neck | 10 | 300LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Weld Neck | 6 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Weld Neck | 4 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Weld Neck | 18 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Weld Neck | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Weld Neck | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |