ZVINHU ZVAKANYANYA

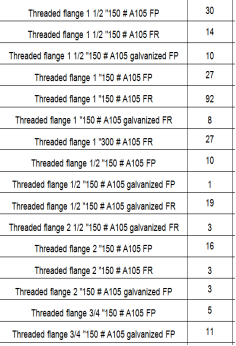

| Zita rechigadzirwa | Chinongedzo cheshinda |

| Saizi | 1/2"-24" |

| Kumanikidzwa | 150#-2500#,PN0.6-PN400,5K-40K |

| Zvakajairika | ANSI B16.5, EN1092-1, JIS B2220 nezvimwe. |

| Rudzi rwakarukwa | NPT ,BSP |

| Zvinhu | Simbi isina ngura:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo nezvimwewo. |

| Simbi yekabhoni:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 nezvimwewo. | |

| Simbi isina ngura mbiri:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 nezvimwewo. | |

| Simbi yemapaipi:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 nezvimwewo. | |

| Nickel alloy:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 nezvimwewo. | |

| Cr-Mo alloy:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, nezvimwewo. | |

| Kushandiswa | Indasitiri yePetrochemical; indasitiri yendege nendege; indasitiri yemishonga; utsi hwegasi; chitubu chemagetsi; kuvaka ngarava; kurapwa kwemvura, nezvimwewo. |

| Zvakanakira | stock yakagadzirira, nguva yekutumira nekukurumidza; inowanikwa muhukuru hwese, yakagadzirirwa; yemhando yepamusoro |

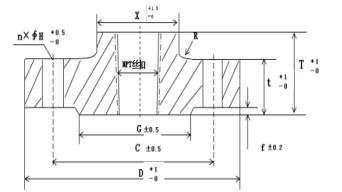

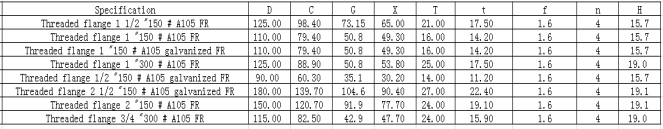

ZVIYERO ZVE DIMENSION

RATIDZA RUDO RWEMAGADZIRWA

1. Chiso

Inogona kusimudzwa pachiso (RF), yakazara pachiso (FF), Ring joint (RTJ), Groove, Tongue, kana yakagadzirirwa iwe.

2. Musoro

NPT kana BSP

3.CNC faini yapera

Kupedzisa kwechiso: Kupedzisa pachiso cheflange kunoyerwa seArithmetical Average Roughness Height (AARH). Kupedzisa kunotsanangurwa nechiyero chinoshandiswa. Semuenzaniso, ANSI B16.5 inotsanangura kupedzisa kwechiso mukati me125AARH-500AARH (3.2Ra kusvika 12.5Ra). Mamwe mafinishe anowanikwa kana uchida, semuenzaniso 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra kana 6.3/12.5Ra. Kupfuura 3.2/6.3Ra ndiko kwakajairika.

KUMAKA UYE KUPAKISA

• Rutivi rumwe nerumwe runoshandisa purasitiki kudzivirira pamusoro

• Kune simbi isingasvibi, mapuranga epurasitiki anoiswa mubhokisi replywood. Kuti mapuranga ecarbon flanges akwanise kukura, mapuranga anoiswa mubhokisi replywood. Kana kuti anogona kurongwa kuti agadziriswe.

• Chiratidzo chekutumira chinogona kuitwa kana chakumbirwa

• Zviratidzo pazvigadzirwa zvinogona kuvezwa kana kudhindwa. OEM inogamuchirwa.

KUONGORORA

• Kuongororwa kweUT

• Kuongororwa kwePT

• Kuongororwa kweMT

• Kuyedzwa kwehukuru

Tisati tasvika, timu yedu yeQC icharonga bvunzo yeNDT uye kuongororwa kwehukuru hwayo.Bvumawo TPI (kuongororwa kwebato rechitatu).

MAITIRO EKUGADZIRA

| 1. Sarudza zvinhu zvepakutanga | 2. Cheka zvinhu zvakabikwa | 3. Kudziisa usati watanga |

| 4. Kugadzira | 5. Kurapa kupisa | 6. Kugadzira Machining Zvakaipa |

| 7. Kuboora | 8. Kugadzira zvakanaka | 9. Kumaka |

| 10. Kuongorora | 11. Kurongedza | 12. Kutumira |

Nyaya yekushandira pamwe

Chirongwa ichi cheBrazil. Zvimwe zvinhu zvinoda mafuta ekudzivirira ngura uye zvimwe zvinoda galvanized coating.

Mibvunzo Inowanzo bvunzwa

1. Chii chinonzi simbi isina ngura 304?

Simbi isingatsvi 304 isimbi isingatsvi simbi inoshandiswa zvakanyanya uye inodzivirira ngura, ine simba rakawanda uye inogadzirwa zvakanaka. Inoshandiswa zvakanyanya mumaindasitiri akasiyana-siyana nekuda kwekushanda kwayo kwakawanda uye kugara kwenguva refu.

2. Chii chinonzi simbi isina ngura 304L?

Simbi isina ngura 304L imhando yesimbi isina ngura 304 ine kabhoni shoma. Inopa mukana wekunamira zvakanaka uku ichiramba iine simba rekudzivirira ngura uye hunhu hwemakanika hwakafanana. Mhando iyi inowanzo shandiswa mukushandisa kunoda kunamira.

3. Chii chinonzi simbi isina ngura 316?

Simbi isingatsvinyi 316 isimbi isingatsvinyi simbi ine molybdenum kuti iwedzere kusimba kwayo mukuora munzvimbo dzemugungwa nedze chloride. Ine simba rakanaka uye inodzivirira kukwira kwemvura zvakanyanya, zvichiita kuti ikwanise kushandiswa kwakasiyana-siyana.

4. Chii chinonzi simbi isina ngura 316L?

Simbi isina ngura ye316L imhando yesimbi isina ngura ine kabhoni shoma ye316. Yakavandudzika pakugona kusvira uye kuramba ngura pakati pegranular. Iyi mhando inowanzoshandiswa mukushandiswa kunoda kuramba ngura zvakanyanya uye kugona kuumba zvakanaka.

5. Ndezvipi zvinhu zvinogadzirwa netambo dzepombi dzakagadzirwa neshinda?

Zvishandiso zvepombi zvakagadzirwa neshinda zvakagadzirwa nesimbi inopisa uye kushandisa simba remuchina kuti zviite chimiro chaunoda. Zvishandiso izvi zvine shinda pamusoro pekunze uye zvinogona kubatanidzwa nyore nyore nepaipi yakagadzirwa neshinda kuti pave nekubatana kwakachengeteka, kusina kubuda kwemvura.

6. Chii chinonzi flange?

Flange imucheto wekunze kana wemukati unoshandiswa kusimbisa kana kubatanidza mapaipi, mavharuvhu, kana zvimwe zvinhu zviri muhurongwa hwemapaipi. Anopa nzira iri nyore yekuunganidza, kupatsanura uye kuchengetedza hurongwa. Flange dzesimbi dzisina ngura dzinodzivirira ngura zvakanaka uye dzinogona kutsungirira kupisa kwakanyanya.

7. Ndezvipi zvinodiwa zveASTM zvezvishandiso zve threaded fittings uye flanges?

ASTM zviyero zvinozivikanwa pasi rose zvakagadzirwa neAmerican Society for Testing and Materials. Izvi zviyero zvinovimbisa kuti fittings dzakagadzirwa neshinda uye flanges zvinosangana nezvinodiwa chaizvo zvekuumbwa kwezvinhu, saizi, hunhu hwemakanika uye maitiro ekuyedza.

8. Ndezvipi zvakanakira kushandisa simbi isina ngura yakagadzirwa neshinda dzakagadzirwa nesimbi isina ngura uye flanges?

Zvishandiso zvemapaipi zvakagadzirwa nesimbi isina ngura uye flanges zvine mabhenefiti akasiyana-siyana, anosanganisira kuramba ngura zvakanaka, simba rakawanda, kugara kwenguva refu uye kushanduka-shanduka. Zvinogona kutsungirira tembiricha yakanyanya, kumanikidzwa uye mamiriro ekunze akaomarara, zvichiita kuti zvikwanise kushandiswa zvakasiyana-siyana.

9. Zvishandiso zvemapaipi zvakagadzirwa nesimbi isina ngura uye flanges zvinowanzo shandiswa muminda ipi?

Zvishandiso izvi zvinoshandiswa zvakanyanya mumaindasitiri akadai semafuta negesi, petrochemical, makemikari, kugadzira magetsi, mishonga, pulp nemapepa, kugadzira chikafu uye kugadzirisa mvura. Zvinowanzoshandiswa mumapombi, mapaipi, nzvimbo dzekuchenesera mvura nedzimwe nzvimbo uko kunoda kubatana kwakachengeteka uye kushanda kwakavimbika.

10. Ungasarudza sei zvinhu zvakakodzera zvesimbi isina ngura zvakagadzirwa neshinda dzakaputirwa?

Kuti usarudze mafittings nemaflanges akakodzera, funga nezvezvinhu zvakaita sezvinodiwa pakushandisa, mamiriro ekushanda (tembiricha, kumanikidzwa, uye nharaunda dzinopisa), saizi yepombi, uye kuenderana nemvura iri kutakurwa. Zvinokurudzirwa kubvunza mutengesi ane ruzivo kana mainjiniya kuti akupe gwara rekusarudza mafittings nemaflanges anokodzera zvaunoda.

Zvishandiso zvepombi zvinhu zvakakosha muhurongwa hwemapaipi, zvinoshandiswa pakubatanidza, kudzoreredza, kutsausa, kuchinja saizi, kuvhara kana kudzora kuyerera kwemvura. Zvinoshandiswa zvakanyanya mumabasa akadai sekuvaka, maindasitiri, simba uye mabasa emakanzuru.

Mabasa Akakosha:Inogona kuita mabasa akadai sekubatanidza mapaipi, kushandura nzira yekuyerera kwemvura, kupatsanura nekubatanidza kuyerera kwemvura, kugadzirisa dhayamita yemapaipi, kuvhara mapaipi, kudzora nekugadzirisa.

Mashandisirwo Ekushandisa:

- Kuvaka mvura uye nzira dzekubvisa mvura:Magokora ePVC nePPR tris zvinoshandiswa pakubatanidza mapaipi emvura.

- Mapaipi emaindasitiri:Maflange esimbi isina ngura uye magokora esimbi alloy anoshandiswa kutakura zvinhu zvine makemikari.

- Kutakurwa kwesimba:Zvishandiso zvesimbi zvine simba guru zvinoshandiswa mumapaipi emafuta negesi.

- HVAC (Kudziisa, Kufefetedza, uye Kutonhodza Mhepo):Zvishandiso zvemapaipi emhangura zvinoshandiswa kubatanidza mapaipi emufiriji, uye majoini anochinjika anoshandiswa kuderedza kudedera.

- Kudiridza kwekurima:Zvinobatanidza zvinokurumidza zvinoita kuti zvive nyore kuunganidza nekuputsa masisitimu ekudiridza sprinkler.

-

Socket weld flange A105 kabhoni simbi SW RTJ 3/4 ...

-

ASTM A182 F51 F53 BL ANSI B16.5 Simbi isina ngura...

-

Simbi Isina Kusimba 304 304L 316 316L ASTM yakagadzirwa ...

-

ANSI B16.5 Yakagadziriswa Simbi Isina Kugadzika Soketi Yesimbi F ...

-

ANSI DIN Forged Class150 Stainless Steel Slip o ...

-

Flange yakagadzirwa ANSI/ASME/JIS Standard Carbon ...