KUTAURA

| Product Name | Lap joint/Lose flange |

| Size | 1/2"-24" |

| Pressure | 150#-2500#,PN0.6-PN400,5K-40K |

| Standard | ANSI B16.5, EN1092-1, JIS B2220 nezvimwe. |

| Stub end | MSS SP 43, ASME B16.9 |

| Material | Simbi isina ngura:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1, 1,4347 1.4571,1.4541, 254Mo uye nezvimwe. |

| Carbon steel:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 nezvimwewo. | |

| Duplex simbi isina tsvina:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 nezvimwe. | |

| Pipeline simbi:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 zvichingodaro. | |

| Nickel alloy:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 nezvimwe. | |

| Cr-Mo alloy:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, nezvimwewo. | |

| Application | Petrochemical industry; aviation and aerospace industry; pharmaceutical industry; gasi exhaust; power plant; ship building; water treatment, etc. |

| Zvakanakira | yakagadzirira stock, inokurumidza kuburitsa nguva; inowanikwa mumasaizi ese, akagadzirirwa; mhando yepamusoro |

DIMENSION MITIRO

LAP JOINT FLANGE

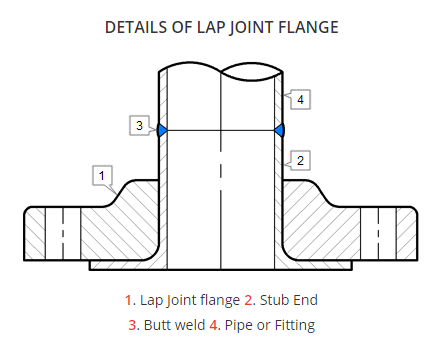

Iyo lap-joint flange inoda mapiping maviri emativi ega ega eiyo flanged yekubatanidza, stub magumo uye yakasununguka backing flange. Iyo yakasununguka backing flange inokwana pamusoro pekunze kwedhayamita ye stub yekupedzisira, iyo inosungirirwa butt kune pombi. Iyo inotsigira flange haina welded kune pombi, uye inogona kutenderedzwa, iyo inonyanya kubatsira kana ichidikanwa kurongedza maflange panguva yekumisa.

Zvakare, sezvo iyo bhegi flange isingasangani neiyo process fluid, inogona kugadzirwa neiyo isingaite corrosive-resistant material. Semuyenzaniso, kana maitiro acho achiora uye achida kuti pombi ive yesimbi isina tsvina, sezvakaita ASTM A312 TP316L, ipapo stub end inofanirawo kugadzirwa neSS 316L; zvisinei, iyo inotsigira flange inogona kugadzirwa yakachipa ASTM A105.

Iyi nzira yekubatanidza haina kusimba seweld neck flange asi yakakwirira pane screwed, socket weld, uye kutsvedza pazvibatanidza; zvisinei, zvinodhura kuuraya, nokuti zvinoda yakazara-inopinda butt weld uye inoda zvikamu zviviri.

STUB END

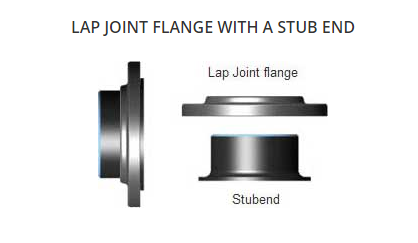

A Stub End inogara ichishandiswa neLap Joint flange, senge inotsigira flange.

Iyi flange yekubatanidza inoiswa, mune yakaderera-kudzvanywa uye isiri yakakosha maapplication, uye inzira yakachipa yeflanging.

Mune simbi isina tsvina yepombi system, semuenzaniso, kabhoni simbi flange inogona kuiswa, nekuti ivo havana kusangana nechigadzirwa mupombi.

Stub Ends inowanikwa munenge ese pombi madhayamita. Dimensions uye dimensional tolerances zvinotsanangurwa muASME B.16.9 mwero. Chiedza-huremu chinodzivirira Stub Ends (fittings) inotsanangurwa muMSS SP43.

INOBATSIRWA YEPAP JOINT FLANGE

- Rusununguko rwekutenderera uchitenderedza pombi runofambisira mutsetse weanopikisa maburi ebhaudhi.

- Kusasangana nemvura mupombi kazhinji kunobvumira kushandiswa kwekabhoni simbi flange isingadhure ine pombi isingadziviriri.

- Mune masisitimu anokoromora kana kuora nekukurumidza, maflange anogona kuchengetwa kuti ashandiswe zvakare.

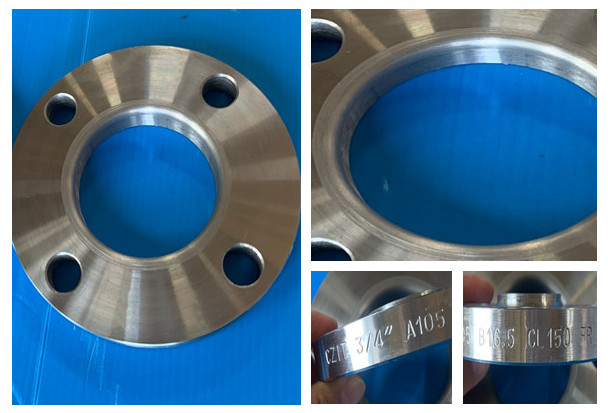

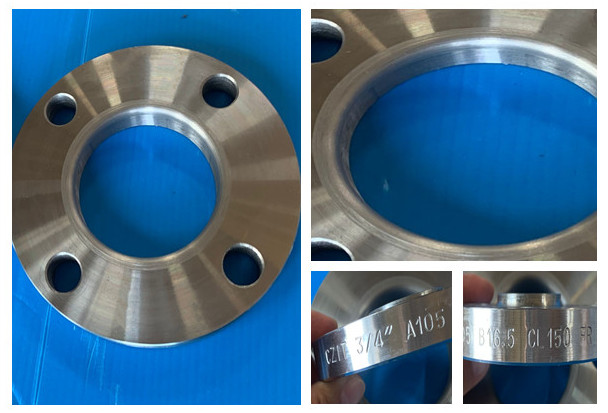

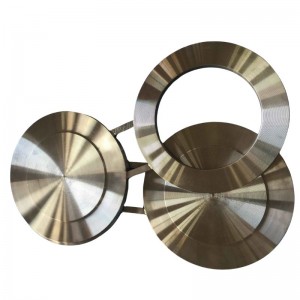

PRODUCTS DETAIL SHOW

1. Chiso

chiso chakapfava, Radhiyasi ndiyo inonyanya kukosha

2. Nehubhu kana isina hubhu

3.Face kupera

Kupedzisa kuri pachiso cheflange kunoyerwa seArithmetical Average Roughness Height(AARH). Kupedzisa kunotsanangurwa nechiyero chinoshandiswa. Semuenzaniso, ANSI B16.5 inotsanangura kupera kwechiso mukati mechikamu 125AARH-500AARH(3.2Ra kusvika 12.5Ra). Mamwe mapedziso anowanikwa pachikumbiro, semuenzaniso 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra kana 6.3/12.5Ra. Iyo yakawanda 3.2 / 6.3Ra ndiyo yakawanda.

KUMAKA NEKUPAKA

• Chigadziko chimwe nechimwe chinoshandisa firimu repurasitiki kuchengetedza pamusoro

• Nokuti zvose Stainless simbi akazara plywood kesi. Kune yakakura saizi kabhoni flange yakarongedzwa neplywood pallet. Kana kuti inogona kugadziriswa packing.

• Mucherechedzo wekutumira unogona kuita pakukumbira

• Kutara pane zvigadzirwa zvinogona kuvezwa kana kudhindwa. OEM inogamuchirwa.

KUONGORORA

• UT bvunzo

• PT bvunzo

• MT bvunzo

• Dimension test

Tisati tasununguka, timu yedu yeQC icharonga NDT bvunzo uye chiyero chekuongorora. Uyewo gamuchira TPI (yechitatu bato kuongorora).

PRODUCTION PROCESS

| 1. Sarudza Genuine raw material | 2. Cheka mbishi | 3. Pre-kupisa |

| 4. Kugadzira | 5. Kurapa kwekupisa | 6. Rough Machining |

| 7. Kuchera | 8. Kuita zvakanaka | 9. Kumaka |

| 10. Kuongorora | 11. Kurongedza | 12. Delivery |

Iyo lap-joint flange inoda mapiping maviri emativi ega ega eiyo flanged yekubatanidza, stub magumo uye yakasununguka backing flange. Iyo yakasununguka backing flange inokwana pamusoro pekunze kwedhayamita ye stub yekupedzisira, iyo inosungirirwa butt kune pombi. Iyo inotsigira flange haina welded kune pombi, uye inogona kutenderedzwa, iyo inonyanya kubatsira kana ichidikanwa kurongedza maflange panguva yekumisa.

Zvakare, sezvo iyo bhegi flange isingasangani neiyo process fluid, inogona kugadzirwa neiyo isingaite corrosive-resistant material. Semuyenzaniso, kana maitiro acho achiora uye achida kuti pombi ive yesimbi isina tsvina, sezvakaita ASTM A312 TP316L, ipapo stub end inofanirawo kugadzirwa neSS 316L; zvisinei, iyo inotsigira flange inogona kugadzirwa yakachipa ASTM A105.

Iyi nzira yekubatanidza haina kusimba seweld neck flange asi yakakwirira pane screwed, socket weld, uye kutsvedza pazvibatanidza; zvisinei, zvinodhura kuuraya, nokuti zvinoda yakazara-inopinda butt weld uye inoda zvikamu zviviri.

A Stub End inogara ichishandiswa neLap Joint flange, senge inotsigira flange.

Iyi flange yekubatanidza inoiswa, mune yakaderera-kudzvanywa uye isiri yakakosha maapplication, uye inzira yakachipa yeflanging.

Mune simbi isina tsvina yepombi system, semuenzaniso, kabhoni simbi flange inogona kuiswa, nekuti ivo havana kusangana nechigadzirwa mupombi.

Stub Ends inowanikwa munenge ese pombi madhayamita. Dimensions uye dimensional tolerances zvinotsanangurwa muASME B.16.9 mwero. Chiedza-huremu chinodzivirira Stub Ends (fittings) inotsanangurwa muMSS SP43.

- Rusununguko rwekutenderera uchitenderedza pombi runofambisira mutsetse weanopikisa maburi ebhaudhi.

- Kusasangana nemvura mupombi kazhinji kunobvumira kushandiswa kwekabhoni simbi flange isingadhure ine pombi isingadziviriri.

- Mune masisitimu anokoromora kana kuora nekukurumidza, maflange anogona kuchengetwa kuti ashandiswe zvakare.

Zvigadzirwa zvakadzama zvinoratidza

1. Chiso

chiso chakapfava, Radhiyasi ndiyo inonyanya kukosha

2. Nehubhu kana isina hubhu

3.Face kupera

Kupedzisa kuri pachiso cheflange kunoyerwa seArithmetical Average Roughness Height(AARH). Kupedzisa kunotsanangurwa nechiyero chinoshandiswa. Semuenzaniso, ANSI B16.5 inotsanangura kupera kwechiso mukati mechikamu 125AARH-500AARH(3.2Ra kusvika 12.5Ra). Mamwe mapedziso anowanikwa pachikumbiro, semuenzaniso 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra kana 6.3/12.5Ra. Iyo yakawanda 3.2 / 6.3Ra ndiyo yakawanda.

Kumaka uye kurongedza

• Chigadziko chimwe nechimwe chinoshandisa firimu repurasitiki kuchengetedza pamusoro

• Nokuti zvose Stainless simbi akazara plywood kesi. Kune yakakura saizi kabhoni flange yakarongedzwa neplywood pallet. Kana kuti inogona kugadziriswa packing.

• Mucherechedzo wekutumira unogona kuita pakukumbira

• Kutara pane zvigadzirwa zvinogona kuvezwa kana kudhindwa. OEM inogamuchirwa.

Inspection

• UT bvunzo

• PT bvunzo

• MT bvunzo

• Dimension test

Tisati tasununguka, timu yedu yeQC icharonga NDT bvunzo uye chiyero chekuongorora. Uyewo gamuchira TPI (yechitatu bato kuongorora).

Nzira yekugadzira

| 1. Sarudza Genuine raw material | 2. Cheka mbishi | 3. Pre-kupisa |

| 4. Kugadzira | 5. Kurapa kwekupisa | 6. Rough Machining |

| 7. Kuchera | 8. Kuita zvakanaka | 9. Kumaka |

| 10. Kuongorora | 11. Kurongedza | 12. Delivery |

-

ASTM A182 F51 F53 BL ANSI B16.5 Simbi isina tsvina...

-

A105 150lb Dn150 kabhoni simbi welding slip paf...

-

Mugadziri ane hunyanzvi hwekuumba-high-pressure ...

-

paddle blank spacer A515 gr 60 chimiro 8 chitarisiko...

-

ASME b16.48 Factory Kutengesa kabhoni simbi mufananidzo 8 ...

-

kabhoni simbi a105 forge bofu BL flange