ZVINHU ZVAKANYANYA

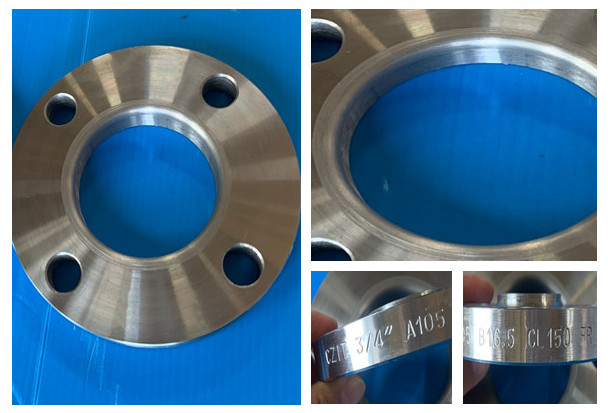

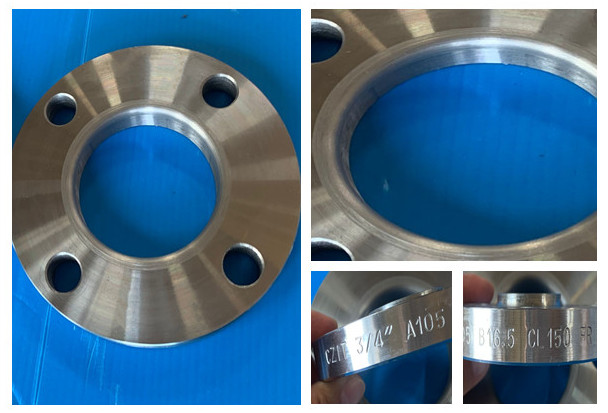

| Zita rechigadzirwa | Chibatanidzwa chemakumbo/Flange yakasununguka |

| Saizi | 1/2"-24" |

| Kumanikidzwa | 150#-2500#,PN0.6-PN400,5K-40K |

| Zvakajairika | ANSI B16.5, EN1092-1, JIS B2220 nezvimwe. |

| Mugumo we stub | MSS SP 43, ASME B16.9 |

| Zvinhu | Simbi isina ngura:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo nezvimwewo. |

| Simbi yekabhoni:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 nezvimwewo. | |

| Simbi isina ngura mbiri:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 nezvimwewo. | |

| Simbi yemapaipi:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 nezvimwewo. | |

| Nickel alloy:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H,C22, C-276, Monel400, Alloy20 nezvimwewo. | |

| Cr-Mo alloy:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, nezvimwewo. | |

| Kushandiswa | Indasitiri yePetrochemical; indasitiri yendege nendege; indasitiri yemishonga; utsi hwegasi; chitubu chemagetsi; kuvaka ngarava; kurapwa kwemvura, nezvimwewo. |

| Zvakanakira | stock yakagadzirira, nguva yekutumira nekukurumidza; inowanikwa muhukuru hwese, yakagadzirirwa; yemhando yepamusoro |

ZVIYERO ZVE DIMENSION

FLANGE YEKUPEDZA PAMHEPO

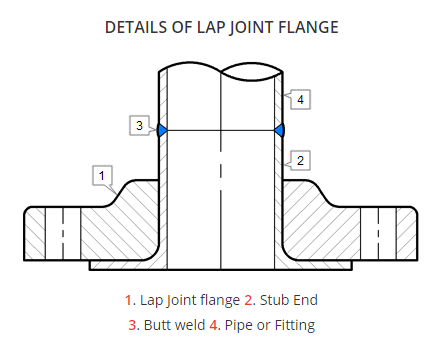

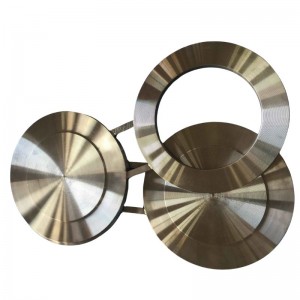

Flange ine lap-joint inoda zvikamu zviviri zvepombi kumativi ese e flange, stub end uye loose backing flange. Loose backing flange inokodzera pamusoro pe dhayamita yekunze ye stub end, iyo yakasungirirwa kumabutt kupombi. Back flange haina weld kupombi, uye inogona kutenderedzwa, izvo zvinonyanya kubatsira kana zvichidikanwa kutenderedza flanges panguva yekumira.

Uyewo, sezvo flange yekumashure isingabatani ne process fluid, inogona kugadzirwa nezvinhu zvisinganyanyi kukuvadza. Semuenzaniso, kana process yacho ichikuvadza uye ichida kuti pombi ive yesimbi isingatsvedzeri, sezvakaita muASTM A312 TP316L, saka stub end inofanirawo kugadzirwa neSS 316L; zvisinei, flange yekumashure inogona kugadzirwa neASTM A105 yakachipa.

Nzira iyi yekubatanidza haina kusimba seweld neck flange asi iri nani pane screwed, socket weld, uye slip on connections; zvisinei, inodhura kuita izvi, nekuti inoda full-penetration butt weld uye inoda zvikamu zviviri.

MUGUMO WOKUPEDZISIRA

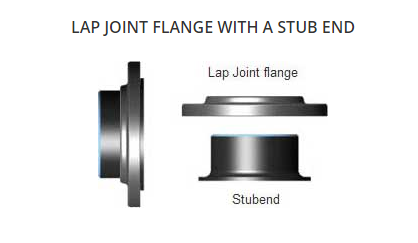

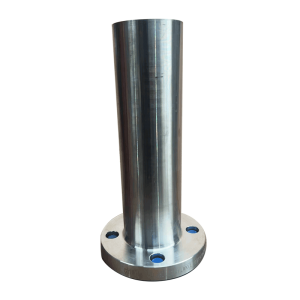

Stub End inogara ichishandiswa neLap Joint flange, se backing flange.

Kubatanidza flange uku kunoshandiswa, mukushandiswa kusingadhuri uye kusiri kwakakosha, uye inzira yakachipa yekuputira.

Semuenzaniso, muhurongwa hwemapaipi esimbi isina ngura, flange yesimbi yekabhoni inogona kuiswa, nekuti haibatani nechigadzirwa chiri mupaipi.

MaStub Ends anowanikwa munenge madhayamita ese epombi. Zviyero uye kushivirira kwezvikamu zvinotsanangurwa muASME B.16.9 standard. MaStub Ends (fittings) anodzivirira ngura anotsanangurwa muMSS SP43.

Yakanakira Lap Joint Flange

- Rusununguko rwekutenderedza pombi runobatsira kuti maburi emabhaudhi eflange akwire.

- Kusasangana nemvura iri mupombi kunowanzo bvumidza kushandiswa kwesimbi dzekabhoni dzisingadhuri dzine mapaipi anodzivirira ngura.

- Mumasystem anopwanyika kana kuora nekukurumidza, maflange anogona kuchengetwa kuti ashandiswezve.

RATIDZA RUDO RWEMAGADZIRWA

1. Chiso

chiso chakati sandara, Radius ndiyo inonyanya kukosha

2. Nehub kana kuti pasina hub

3. Kupedzisa kwechiso

Kupera kweflange kunoyerwa seArithmetical Average Roughness Height (AARH). Kupera kunotsanangurwa nechiyero chinoshandiswa. Semuenzaniso, ANSI B16.5 inotsanangura kupedzisa kwechiso mukati me125AARH-500AARH (3.2Ra kusvika 12.5Ra). Mamwe mafinishe anowanikwa kana uchida, semuenzaniso 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra kana 6.3/12.5Ra. Kureba kwe3.2/6.3Ra ndiko kwakajairika.

KUMAKA UYE KUPAKISA

• Rutivi rumwe nerumwe runoshandisa purasitiki kudzivirira pamusoro

• Kune simbi isingasvibi, mapuranga epurasitiki anoiswa mubhokisi replywood. Kuti mapuranga ecarbon flanges akwanise kukura, mapuranga anoiswa mubhokisi replywood. Kana kuti anogona kurongwa kuti agadziriswe.

• Chiratidzo chekutumira chinogona kuitwa kana chakumbirwa

• Zviratidzo pazvigadzirwa zvinogona kuvezwa kana kudhindwa. OEM inogamuchirwa.

KUONGORORA

• Kuongororwa kweUT

• Kuongororwa kwePT

• Kuongororwa kweMT

• Kuyedzwa kwehukuru

Tisati tasvika, timu yedu yeQC icharonga bvunzo yeNDT uye kuongororwa kwehukuru hwayo. Inogamuchirawo TPI (kuongororwa kwebato rechitatu).

MAITIRO EKUGADZIRA

| 1. Sarudza zvinhu zvepakutanga | 2. Cheka zvinhu zvakabikwa | 3. Kudziisa usati watanga |

| 4. Kugadzira | 5. Kurapa kupisa | 6. Kugadzira Machining Zvakaipa |

| 7. Kuboora | 8. Kugadzira zvakanaka | 9. Kumaka |

| 10. Kuongorora | 11. Kurongedza | 12. Kutumira |

Flange ine lap-joint inoda zvikamu zviviri zvepombi kumativi ese e flange, stub end uye backing flange yakasununguka. Flange yakasununguka backing inokodzera pamusoro pe dhayamita yekunze ye stub end, iyo yakasungirirwa kumabutt kupombi. Backing flange haina weld kupombi, uye inogona kutenderedzwa, izvo zvinonyanya kubatsira kana zvichidikanwa kutenderedza flanges panguva yekumira.

Uyewo, sezvo flange yekumashure isingabatani ne process fluid, inogona kugadzirwa nezvinhu zvisinganyanyi kukuvadza. Semuenzaniso, kana process yacho ichikuvadza uye ichida kuti pombi ive yesimbi isingatsvedzeri, sezvakaita muASTM A312 TP316L, saka stub end inofanirawo kugadzirwa neSS 316L; zvisinei, flange yekumashure inogona kugadzirwa neASTM A105 yakachipa.

Nzira iyi yekubatanidza haina kusimba seweld neck flange asi iri nani pane screwed, socket weld, uye slip on connections; zvisinei, inodhura kuita izvi, nekuti inoda full-penetration butt weld uye inoda zvikamu zviviri.

Stub End inogara ichishandiswa neLap Joint flange, se backing flange.

Kubatanidza flange uku kunoshandiswa, mukushandiswa kusingadhuri uye kusiri kwakakosha, uye inzira yakachipa yekuputira.

Semuenzaniso, muhurongwa hwemapaipi esimbi isina ngura, flange yesimbi yekabhoni inogona kuiswa, nekuti haibatani nechigadzirwa chiri mupaipi.

MaStub Ends anowanikwa munenge madhayamita ese epombi. Zviyero uye kushivirira kwezvikamu zvinotsanangurwa muASME B.16.9 standard. MaStub Ends (fittings) anodzivirira ngura anotsanangurwa muMSS SP43.

- Rusununguko rwekutenderedza pombi runobatsira kuti maburi emabhaudhi eflange akwire.

- Kusasangana nemvura iri mupombi kunowanzo bvumidza kushandiswa kwesimbi dzekabhoni dzisingadhuri dzine mapaipi anodzivirira ngura.

- Mumasystem anopwanyika kana kuora nekukurumidza, maflange anogona kuchengetwa kuti ashandiswezve.

Zvigadzirwa zvakadzama zvinoratidzwa

1. Chiso

chiso chakati sandara, Radius ndiyo inonyanya kukosha

2. Nehub kana kuti pasina hub

3. Kupedzisa kwechiso

Kupera kweflange kunoyerwa seArithmetical Average Roughness Height (AARH). Kupera kunotsanangurwa nechiyero chinoshandiswa. Semuenzaniso, ANSI B16.5 inotsanangura kupedzisa kwechiso mukati me125AARH-500AARH (3.2Ra kusvika 12.5Ra). Mamwe mafinishe anowanikwa kana uchida, semuenzaniso 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra kana 6.3/12.5Ra. Kureba kwe3.2/6.3Ra ndiko kwakajairika.

Kumaka uye kurongedza

• Rutivi rumwe nerumwe runoshandisa purasitiki kudzivirira pamusoro

• Kune simbi isingasvibi, mapuranga epurasitiki anoiswa mubhokisi replywood. Kuti mapuranga ecarbon flanges akwanise kukura, mapuranga anoiswa mubhokisi replywood. Kana kuti anogona kurongwa kuti agadziriswe.

• Chiratidzo chekutumira chinogona kuitwa kana chakumbirwa

• Zviratidzo pazvigadzirwa zvinogona kuvezwa kana kudhindwa. OEM inogamuchirwa.

Kuongorora

• Kuongororwa kweUT

• Kuongororwa kwePT

• Kuongororwa kweMT

• Kuyedzwa kwehukuru

Tisati tasvika, timu yedu yeQC icharonga bvunzo yeNDT uye kuongororwa kwehukuru hwayo. Inogamuchirawo TPI (kuongororwa kwebato rechitatu).

Maitiro ekugadzira

| 1. Sarudza zvinhu zvepakutanga | 2. Cheka zvinhu zvakabikwa | 3. Kudziisa usati watanga |

| 4. Kugadzira | 5. Kurapa kupisa | 6. Kugadzira Machining Zvakaipa |

| 7. Kuboora | 8. Kugadzira zvakanaka | 9. Kumaka |

| 10. Kuongorora | 11. Kurongedza | 12. Kutumira |

Zvishandiso zvepombi zvinhu zvakakosha muhurongwa hwemapaipi, zvinoshandiswa pakubatanidza, kudzoreredza, kutsausa, kuchinja saizi, kuvhara kana kudzora kuyerera kwemvura. Zvinoshandiswa zvakanyanya mumabasa akadai sekuvaka, maindasitiri, simba uye mabasa emakanzuru.

Mabasa Akakosha:Inogona kuita mabasa akadai sekubatanidza mapaipi, kushandura nzira yekuyerera kwemvura, kupatsanura nekubatanidza kuyerera kwemvura, kugadzirisa dhayamita yemapaipi, kuvhara mapaipi, kudzora nekugadzirisa.

Mashandisirwo Ekushandisa:

- Kuvaka mvura uye nzira dzekubvisa mvura:Magokora ePVC nePPR tris zvinoshandiswa pakubatanidza mapaipi emvura.

- Mapaipi emaindasitiri:Maflange esimbi isina ngura uye magokora esimbi alloy anoshandiswa kutakura zvinhu zvine makemikari.

- Kutakurwa kwesimba:Zvishandiso zvesimbi zvine simba guru zvinoshandiswa mumapaipi emafuta negesi.

- HVAC (Kudziisa, Kufefetedza, uye Kutonhodza Mhepo):Zvishandiso zvemapaipi emhangura zvinoshandiswa kubatanidza mapaipi emufiriji, uye majoini anochinjika anoshandiswa kuderedza kudedera.

- Kudiridza kwekurima:Zvinobatanidza zvinokurumidza zvinoita kuti zvive nyore kuunganidza nekuputsa masisitimu ekudiridza sprinkler.

-

Ansi B16.5 A105 Simbi yeKabhoni Nhema Inotsvedza paFlange

-

Yakagadziriswa Isina-Standard Tube Sheet Flange Stain ...

-

ASME b16.48 Kutengeswa kwefekitori simbi yekabhoni mufananidzo 8 ...

-

Simbi Isina Kusimba 304 304L 316 316L ASTM yakagadzirwa ...

-

Long Weld Neck Flange Standard Pressure LWN Ye ...

-

ANSI B16.5 Yakagadziriswa Simbi Isina Kugadzika Soketi Yesimbi F ...